Press from Atuo Recycling World

Recycling significantly reduces the carbon footprint of EV batteries. Botree offers an advanced solution for recycling critical battery materials. Dr Xue Wang, Co-founder & CMO, discusses how Botree’s innovative processes make battery production more sustainable and efficient, helping achieve global carbon neutrality goals.

The rapid development of the battery industry enables the world towards electrification of transportation and mobility, which is undoubtedly the current mainstream. How to produce and recycle battery material in a green and sustainable way has become an important topic in achieving global carbon neutrality, which concerns the world. The current battery production, especially the production of lithium-ion battery materials, is an energy-intensive and high-carbon-emission process. Efficiently recovering or regenerating critical materials from used batteries and re-applying them back in new battery production is an effective way to reduce the overall carbon footprint of the battery industry in the coming future.

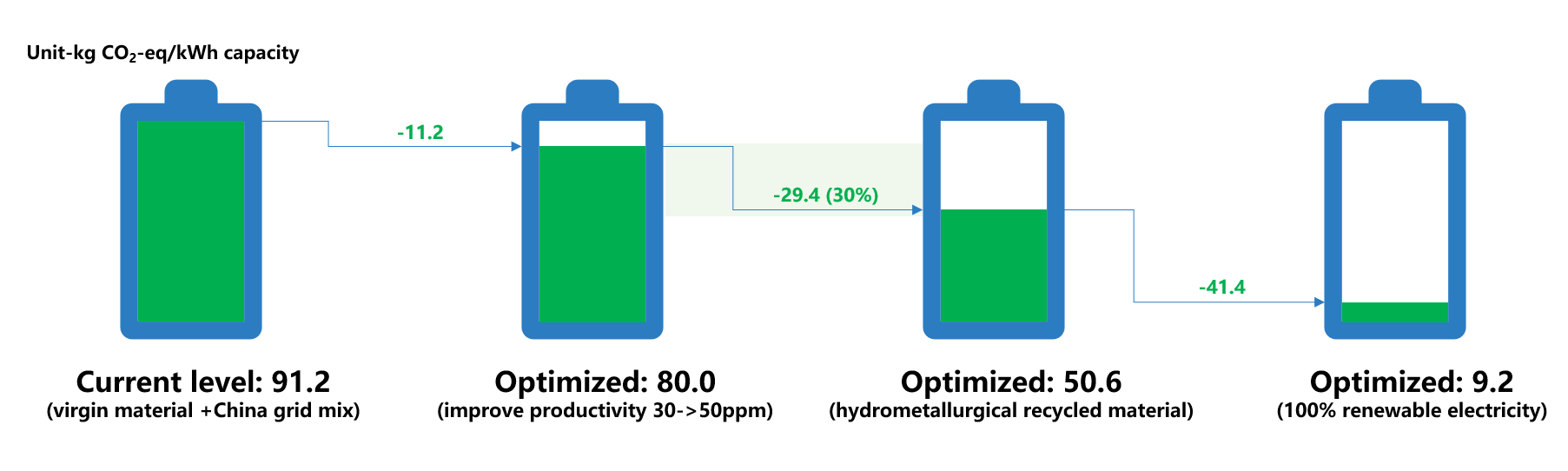

Fig. 1 LIB cell carbon footprint reduction routes (illustrative based on Chen‘s work)[1]

Nevertheless, not all recycling routes will have the same effect; the carbon consulting team from Botree Recycling Technologies has studied and calculated the carbon footprint of three major recycling methods, i.e., pyrometallurgical + hydrometallurgical process, mechanical pre-treatment + hydrometallurgical process, and direct recycling process, considering the whole life cycle of battery materials. It is found that direct recycling demonstrates the highest potential for carbon reduction, though there are still lots of difficulties to overcome before actual industrial application.

The main drawbacks of the pyrometallurgical process are direct carbon emission and relatively low recovery rates for light metal elements. The hydrometallurgical process currently offers the best combination of unit carbon reduction and scale. According to our calculation, replacing the raw materials with recycled materials from the hydrometallurgical process can reduce more than 30% of the carbon footprint.[1] A detailed explanation of the three recycling methods can be found in the appendix.

Fig. 2 Xiao Lin

“Recycling plays a crucial role in the sustainable development of the battery and new energy industry. Botree is aiming to bring the industry with the most efficient and green recycling technologies, helping the real closed loop of battery critical materials, and tackle with climate change issues”, said Xiao Lin, the CEO of Botree Recycling Technologies.

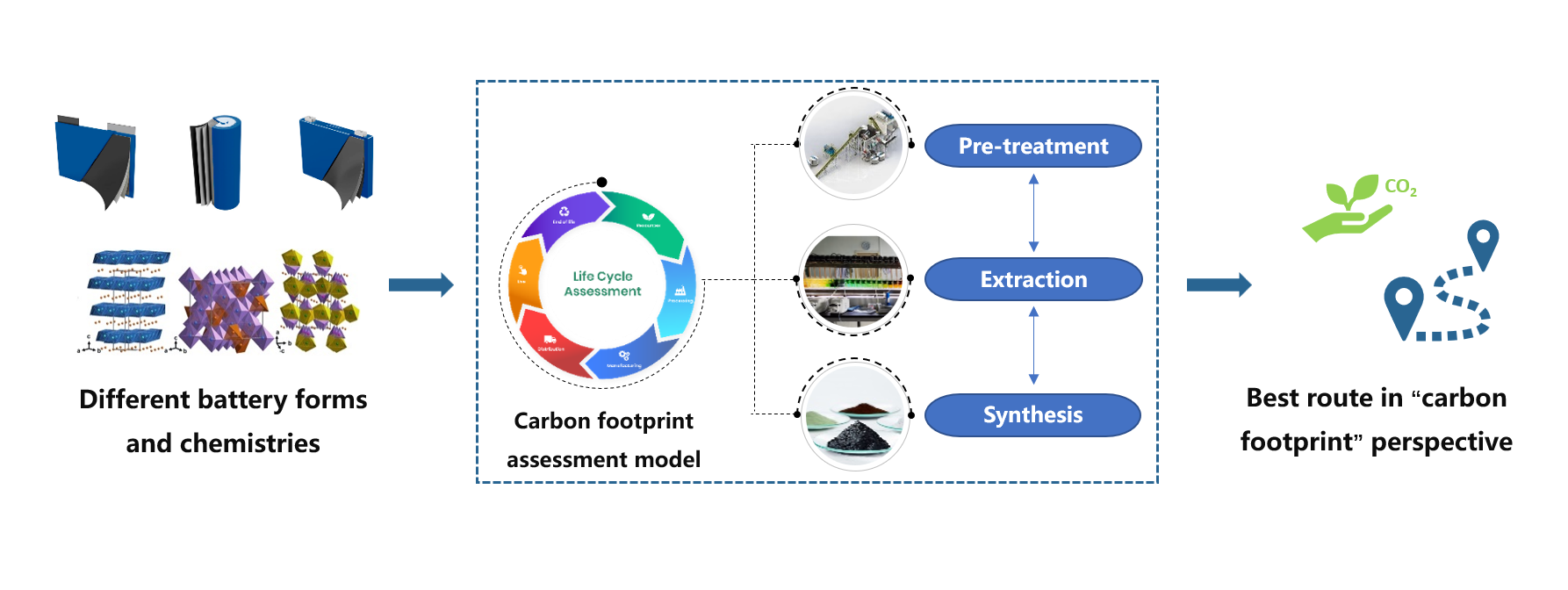

With sustainable development in mind, Botree has developed the carbon footprint assessment model, which can not only trace hotspot emissions but also identify the best recycling route from a carbon footprint perspective. Our engineers are using this model to evaluate new recycling technologies and continuously improve our own recycling processes.

Best power battery recycling technology from a life cycle carbon footprint perspective

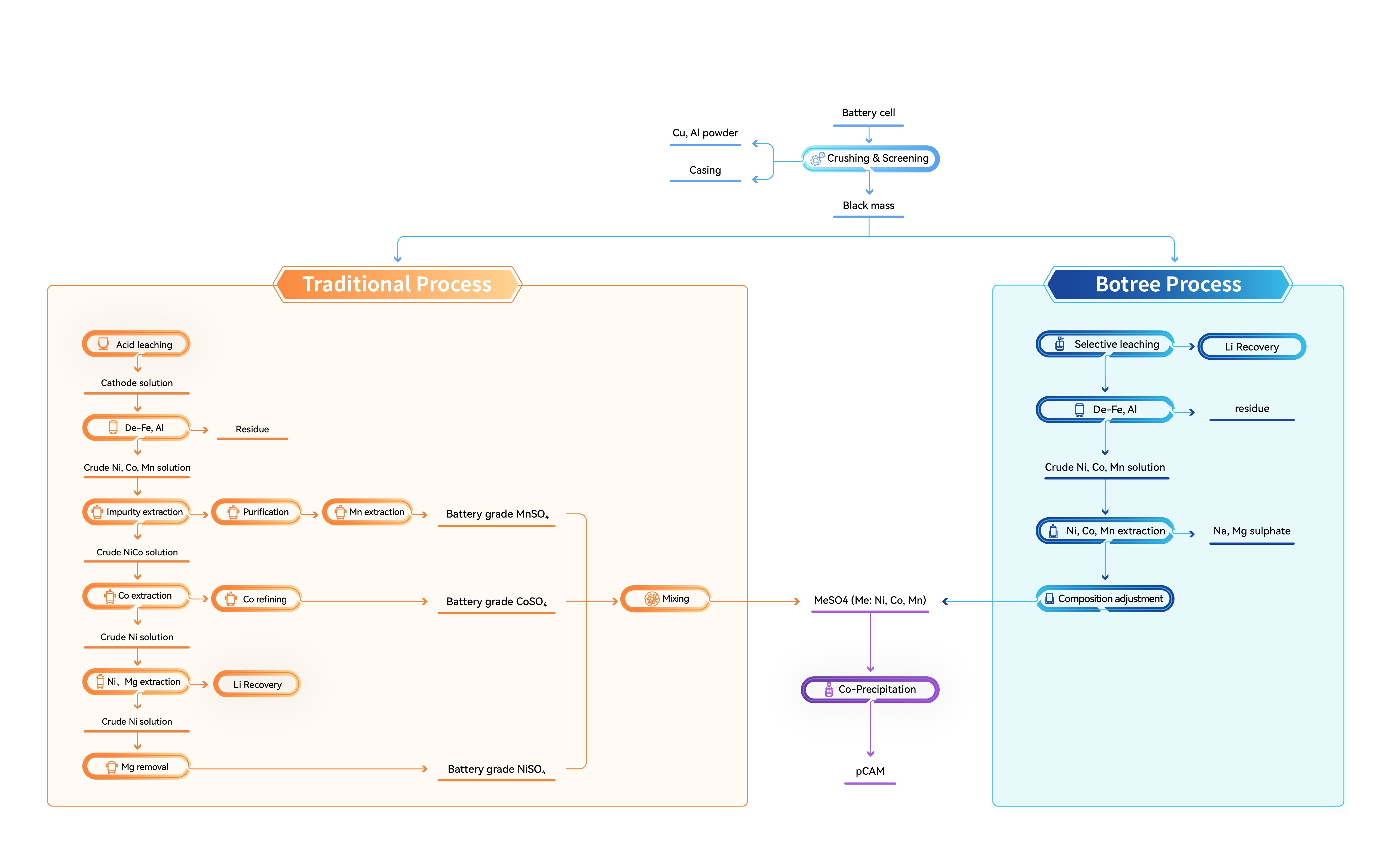

Traditional hydrometallurgical recycling technology for ternary battery material, well known as NCM or NMC, usually involves a long process flow, which extracts Nickel (Ni), Cobalt (Co) and Manganese (Mn) separately and recovers Lithium (Li) at the very end of process flow with low concentration, resulting in a large volume of wastewater, and unnecessarily high chemical, and energy consumption.

To overcome the above-mentioned issues and to make the battery recycling process more efficient, Botree has developed an innovative, concise hydrometallurgical process flow. The comparison of the main process flowchart between the traditional and the one developed by Botree is illustrated below.

Clearly, Botree applies a much shorter and more straightforward process flow compared to the typical process in the market. In Botree’s process flow, the so-called selective leaching + Li recovery in the early stage allows a high Li recovery rate, typically >92%, with at least a 40% reduction in energy consumption. While in the solvent extraction process, Botree’s new novel co-extractant (BC196、211) can simultaneously recover Ni, Co, and Mn, with at least 10% energy reduction, 15% chemical consumption reduction and 40% less wastewater being generated.

More importantly, the recycled mixed solution containing Ni, Co and Mn can be directly used for pCAM synthesis, skipping the crystallisation process and avoiding subsequent transportation and redissolution. Based on our calculation, the recycled materials produced from the new process will reduce at least 3.3 kgCO2-eq per metric kg material (about 15-25% of the average carbon footprint of pCAMs produced in China) carbon footprint compared to the traditional one.

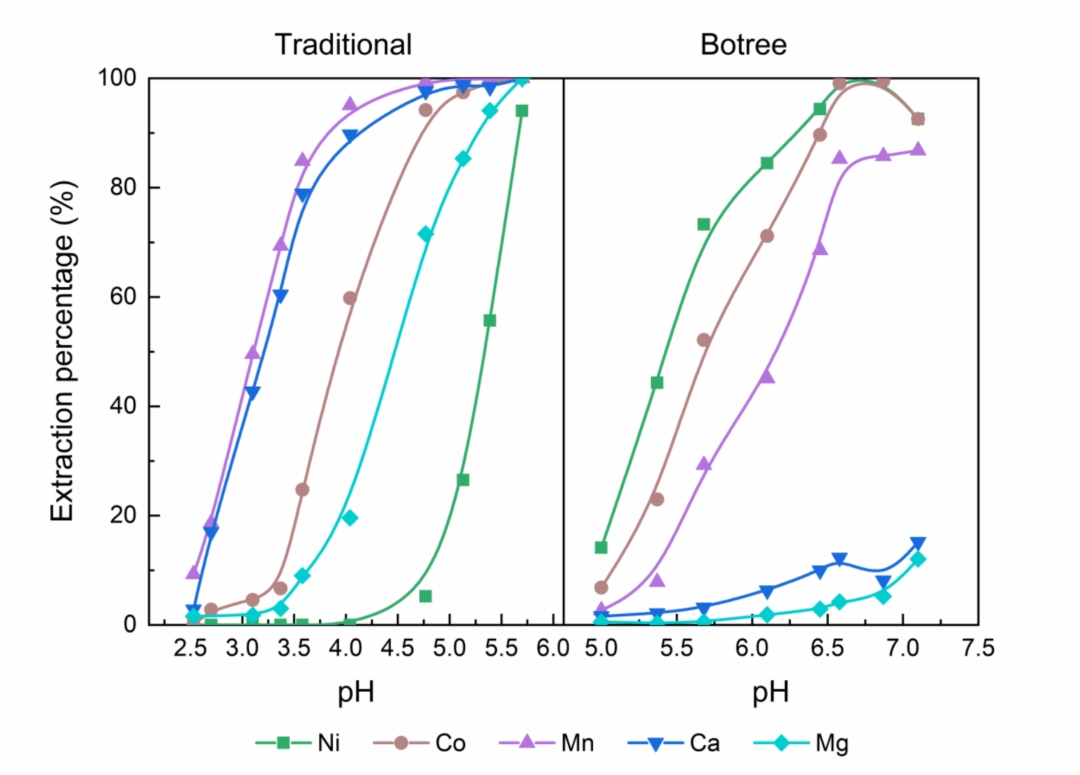

Fig. 5 Extraction percentage of traditional and Botree extractant

Pretreatment

Selective Lithium Extraction

Solvent Extraction

Fig. 6 Demonstration plant or pilot line for Botree’s innovative recycling process

Botree’s carbon consulting team has been actively and deeply working on carbon footprint research for the lithium-ion battery industry. They have also developed various carbon footprint assessment models for different recycling processes with comprehensive project experience.

Looking forward, Botree will continuously support the industry and our customers with greener, more efficient, and reliable recycling technologies, jointly building a sustainable future for the battery as well as new energy industries.

Appendix

Pyrometallurgical + Hydrometallurgical method

Pyrometallurgy is widely used in metal smelting and metal recovery because of its short process and strong adaptability to incoming raw materials. Although the pyrometallurgy process has unique advantages, its high temperature and high energy consumption have raised more concerns considering today’s climate-changing issues.

Mechanical pretreatment + Hydrometallurgical method

Unlike the high temperature pyrometallurgical process, the low temperature hydrometallurgical method is widely used worldwide, especially dominant in China. It generally consists of two major processes: a mechanical pretreatment process followed by a hydrometallurgical process. Normally, no additional chemicals are needed in the pretreatment process. Therefore, the carbon footprint mainly comes from energy consumption.

Unlike mechanical pretreatment, there are a considerable amount of chemicals used during the hydrometallurgical process, including acid and alkali. Thus, the carbon footprint comes from not only the energy consumption related to electricity and low/medium pressure steam being used but also the chemicals being applied.

Direct Recycling method

Direct recycling/recovery of battery cathode materials is realized by using directional lithium replenishment and structural repair without the need for metal salt recycling and battery material regeneration. It can be a low-temperature and low-energy process, using various physical and chemical treatment steps to separate different cell components of spent lithium-ion batteries. The GHG emissions produced in such a direct recovery process are significantly lower than the other two processes due to the simplification of the process flow, which uses fewer chemicals and less energy.

For further information, please visit www.botree.tech

[1] Chen etal., Investigating carbon footprint and carbon reduction potential using a cradle-to-cradle LCA approach on lithium-ion batteries for electric vehicles in China.